Carbon Black Tutorial Pdf

Chemical identity Carbon Black CAS 1333-86-4 is a material consisting of elemental carbon in the form of near spherical colloidal particles and coalesced particle aggregatesagglomerates obtained. The selection of the proper carbon black to use in the production of conductive compounds is based not only on the final properties of the particular compound desired but also on the specific properties of the carbon black.

C Free Full Text Nanostructure Quantification Of Carbon Blacks Html

The International Carbon Black Association ICBA is a scientific non-profit corporation originally founded in 1977.

Carbon black tutorial pdf. Carbon black is not a chemical eye irritant. Different teams like Infrastructure and InfoSec can have a single shared source of truth to improve the security together. Carbon black dust or powder may cause drying of the skin with repeated and prolonged contact.

If symptoms develop seek medical attention. Change log for Carbon Black App Control 852 User Guidepdf changes since the 850 version. Chemical and Physical Specifications 311.

Carbon black dust may be small enough to penetrate electrical boxes and other electrical devices possibly creating electrical hazards resulting in equipment failure. N110 N115 N120 N121 N134 N135 N220 N231 N234 N299 N326 N330 N339. The dispersion level of the carbon black is compared against a series of five photographic standards and then rated numerically from 1.

Tion carbon black volumerubber filled volume. 61 Carbon Black 611 Process Description Carbon black is produced by the reaction of a hydrocarbon fuel such as oil or gas with a limited supply of combustion air at temperatures of 1320 to 1540C 2400 to 2800F. Carbon black is produced with the thermal decomposition method or the partial combustion method using hydrocarbons such as oil or natural gas as raw material.

These fuse into chain-like aggregates which defi ne the structure of individual Carbon Black grades. Change log for Carbon Black App Control 850 User Guidepdf changes since the 8110 version. The purpose of the ICBA is to sponsor conduct and participate in investigations research and analyses relating to the health safety and environmental aspects of the production and use of carbon black.

Carbon black is not a chemical skin irritant. The characteristics of carbon black vary depending on manufacturing process and therefore carbon black is classified by manufacturing process. The unburned carbon is collected as an extremely fine black fluffy particle 10 to 500 nanometers nm in diameter.

Only change was to software version. In the manufacturing process Carbon Black particles are for-med that range from 10 nm to approximately 500 nm in size. Carbon Black Cloud is a cloud-native service that consolidates multiple workload security capabilities using a single easy-to-use console.

By selecting the most appropriate Cabot carbon black for your application you can achieve high levels of opacity performance with reduced loading and cost. Carbon black CB is the most extensively used reinforcing filler in rubber compounds since the discovery of colloidal carbon black reinforcing qualities in 1904. These critical elements of the carbon black are.

Treat symptomatically for mechanical irritation. Extra Conductive Black TB Thermal Black Adhesives and Sealants Conductive Engineering Resins FDA Compliant Fiber Film Geomembranes Pipes Polar Resins COLOUR BLACK FW 171 HCF 137 30 106 80 650 11 COLOUR BLACK FW 285 HCG 116 50 175 35 350 11 COLOUR BLACK FW 255 ST HCF 135 120 106 25 650 11 COLOUR BLACK FW 1 ST HCG 120 50 150 35 320 13. Learn how to conduct focused searches that lead to valuable findings and leverage the rich features found within Endpoint Detection and Response.

VMware Carbon Black EDR Administrator. Description Carbon Black Tutorial Pdf. Rinse eyes with clean water keeping eyelid open.

This one-day instructor-led course provides a technical understanding of Endpoint Detection and Response through comprehensive coursework. Electrical devices that may be exposed to carbon black dust should be tightly sealed or purged with clean air periodically inspected and. Carbon black produced with the furnace.

Carbon black concentration Thus film opacity can be modified by modifying the carbon blackpolymer pairing film thickness andor carbon black concentration. Carbon Black According to the Globally Harmonized System of Classification and Labeling of Chemicals GHS Page 1 of 9 1. PRODUCT AND COMPANY IDENTIFICATION 11 Product name Carbon Black Below are the carbon black grades produced by Sid Richardson Carbon Energy Co.

Summary of Test Method 41 The compound rubber is torn or cut to expose a fresh surface for examination by the eye aided preferably by a hand lens or a low-power binocular microscope. Second revision of the opinion on carbon black nano-form _____ 6 3. By plotting curves using the values of the ratio EfE0 versus C for each carbon black type the shape-factor of each carbon black can be adduced by.

The key carbon black properties are particle size structure and purity. 2728 Carbon black is composed of carbon particles solidly fused together by covalent bonds thus forming aggregates which cannot be broken into smaller sizes during the normal. Carbon Black typically contains more than 95 pure carbon with minimal quantities of oxygen hydrogen and nitrogen.

Quadratic curves of carbon black shape-factor were plotted using Equation 4 by implementing several values of fs 25 3 35 4 and 45.

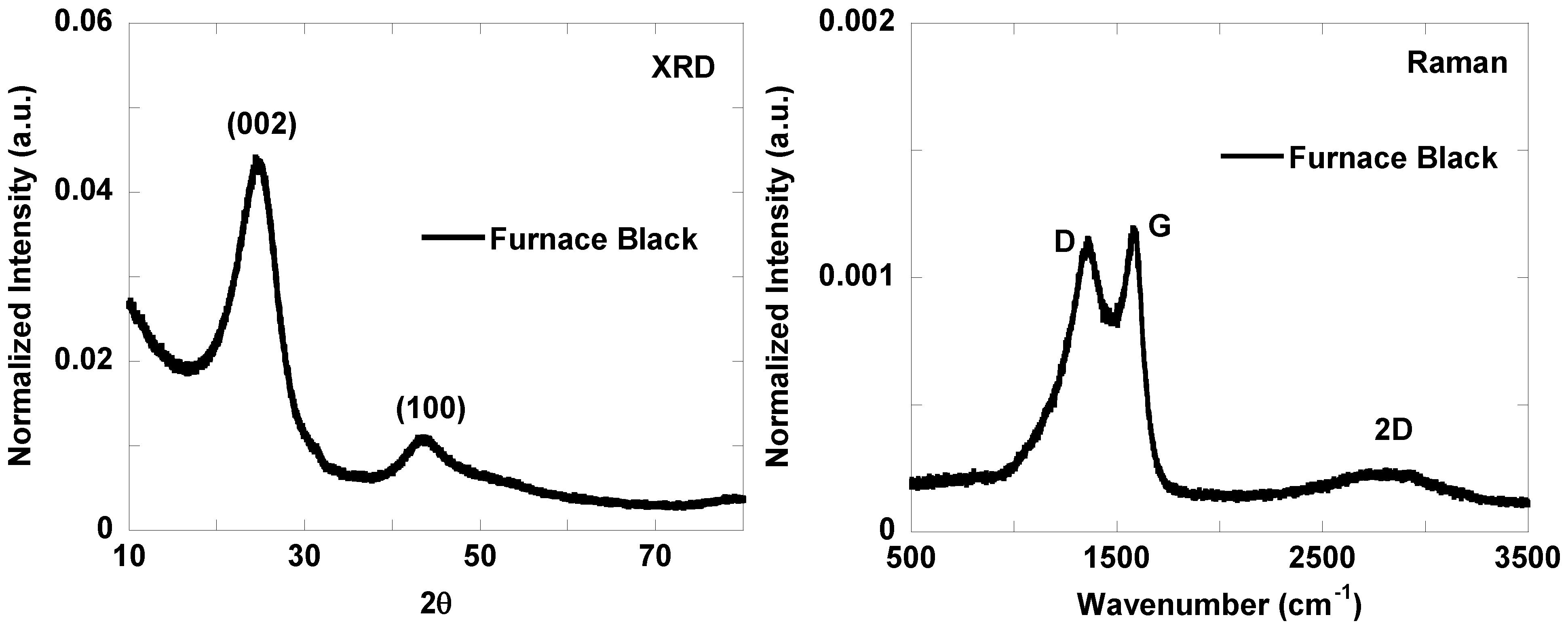

C Free Full Text Structure Of Carbon Materials Explored By Local Transmission Electron Microscopy And Global Powder Diffraction Probes Html

Edr Rest Api Quick Start Carbon Black Developer Network

Our Wiki Everything About Carbon Black Pentacarbon Gmbh

Resource Library Vmware Carbon Black